| Automatic equipment integrating printing, dusting, fixing, drying, and rewinding functions to achieve rapid mass production, save manpower and time, and ensure excellent print quality. |

| Automated production, simple operation, one worker looks at multiple machines, saving labor, shaking powder, drying, wind blowing, one piece printing, pattern printing speed is fast, color change without dots, easy to achieve photo-level effect. |

|

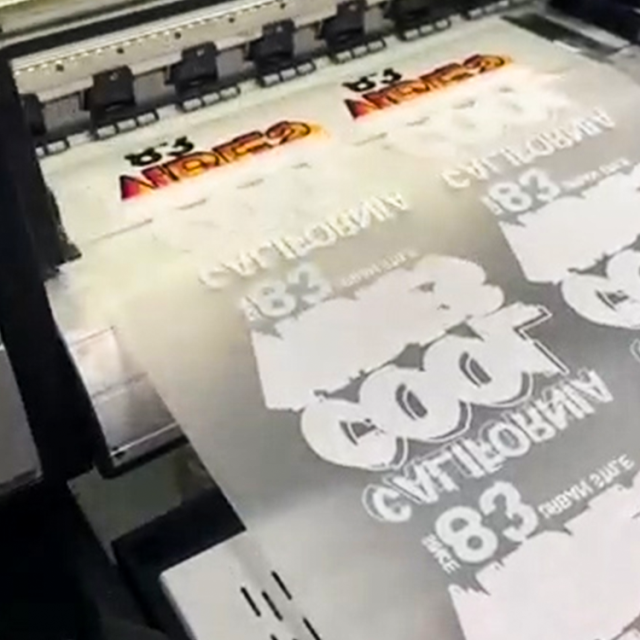

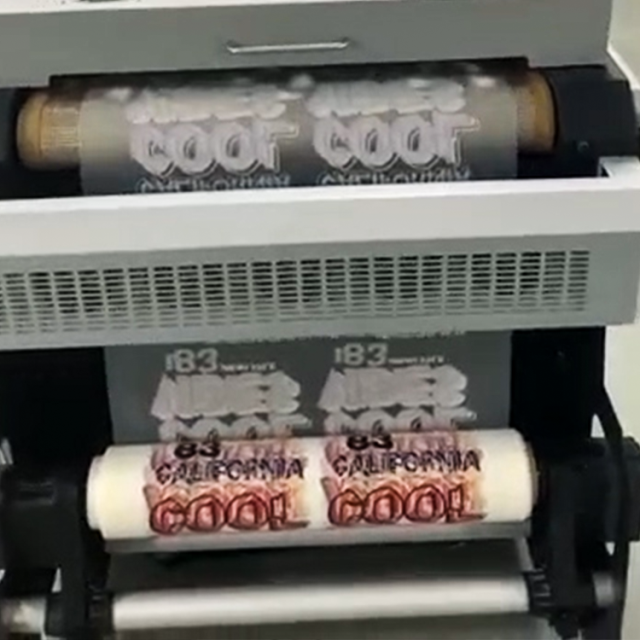

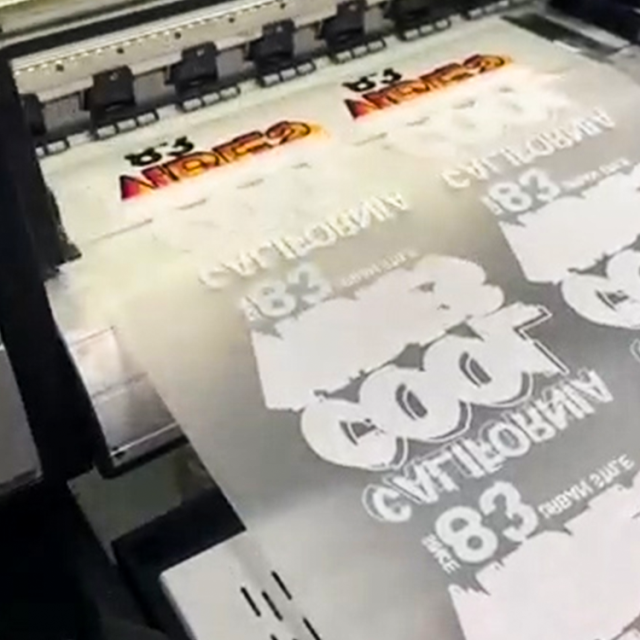

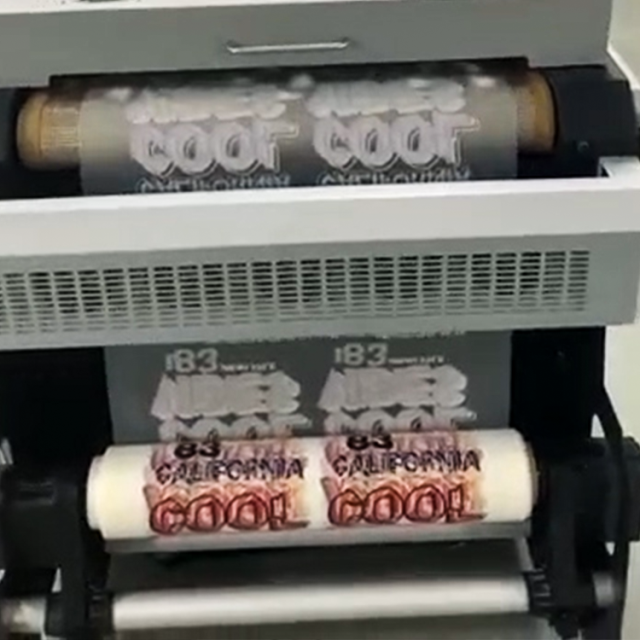

| ① Print pattern |

|

| ② Sprinkle hot melt powder |

|

| ③ Heat fixation |

|

| ④ Rewinding the finished product |

| Using water-based paint ink, good fluency, soft touch, good air permeability, color fastness to washing 4-5, not limited to fabrics, pure cotton, blended, canvas, etc. can be transferred. |

| Epson's unique VSDT (Variable Droplet Technology) can freely control the size of the ejected ink droplets, thereby reducing the graininess of the picture, showing more picture details, smooth color transition and high saturation. Epson printheads are processed with high-precision technology for excellent durability, enabling high-speed output and high-quality printing. |

| One piece of printing, no need for plate making, simple drawing, can be customized in small quantities, or can be produced in large quantities, printing patterns can reach 30 square meters per hour. |